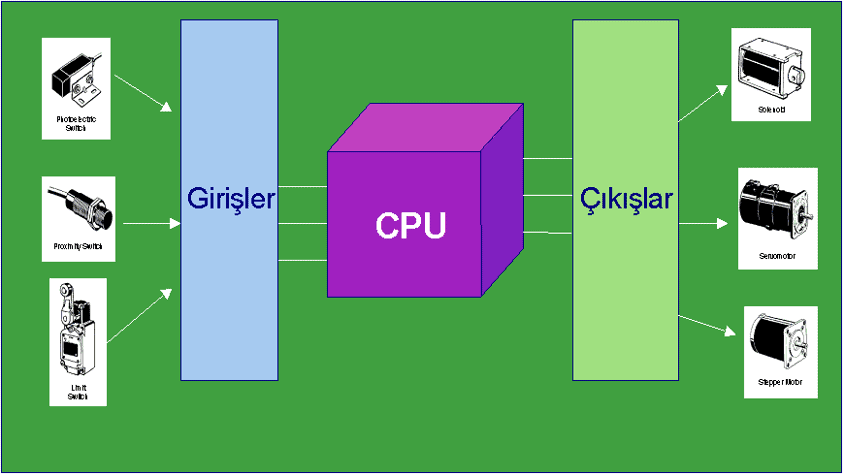

In this article, we will be taking our first step towards PLC, which is the industrial microprocessor that is frequently preferred in automation and control automation systems. PLC stands for “Programmable Logic Controller” in the literature.

The presence of this device, which serves the mission and vision of our company, has actually brought along an industrial revolution. This device, which is the basic structure of Industry 3.0 technology, is actually used in many parts of the industry in the process and production industries today.

Let's list the benefits of this product, which has emerged to replace Relay and Contactor systems;

- The biggest advantage of PLC is that at low voltages, maintenance costs are quite cheap compared to electromechanical relay control systems.

- SIMPLICITY: PLC's modular structure should be able to replace any special applications and systems.

- FEATURES: The modular structure of the PLC should work in a way that responds to all kinds of special applications and extensions of the systems.

- CONVENIENCE: Considering the electro-mechanical system controls and their circuit connections, the space and details of the PLC are quite different according to the work done, so space is saved.

- VARIABILITY: They are general purpose control devices, not mechanical parts of PLC. Additional circuit designs can be made to fulfill many different connections so that the PLC can program repeatedly.

- REALITY: Since PLCs do not have electromechanical parts, they do not have parts to break. PLCs can be stored completely for later use.

PLC can be termed as a digital computer in the industrial field designed to perform, process control and software functions especially for industrial applications. Most PLCs are modular today. Its functions can be increased with add and subtract methods. In addition, users can add or remove analog control, PID control, position control, motor control and communication protocols.

Although it is not similar to the computers we use in our daily life, the structure of the technology seen in the computers and smart equipment that most of us use in our daily lives is seen in the content of PLC.

– Easy to install and assemble.

– It can work uninterruptedly as long as it does not malfunction.

– They take up little space and are compatible with industrial electrical and electronic products.

– Energy consumption is low.

– Does not require much maintenance.

– It can be said that the cost is low when selected for the appropriate job.

– It is more reliable than control systems with relay contactors in bad environmental conditions.

– It ensures that the system in which it is used is more efficient.

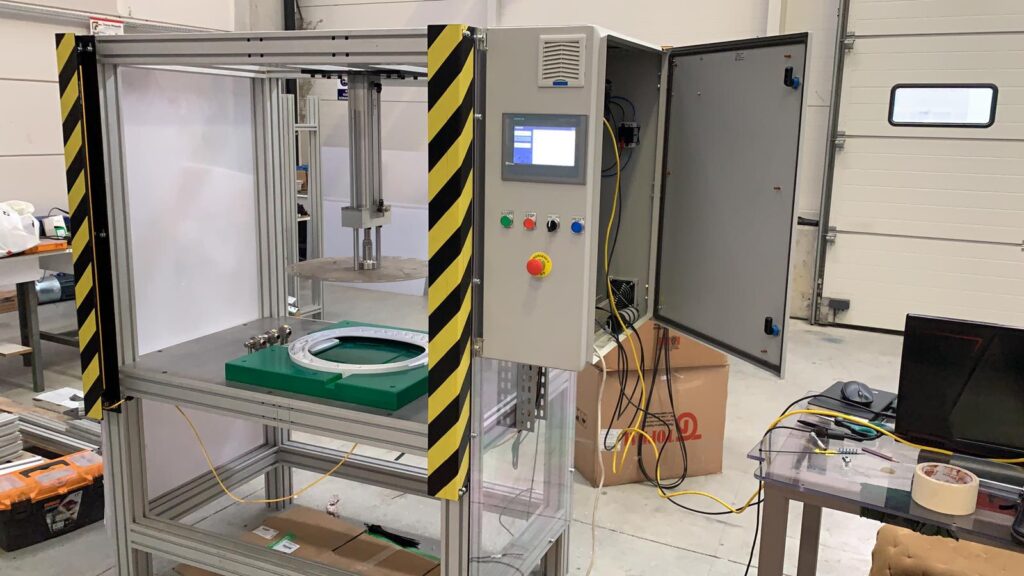

Our company continues to strengthen and support your company with PLC solutions. We end our article with our gallery that we created from some PLC applications.